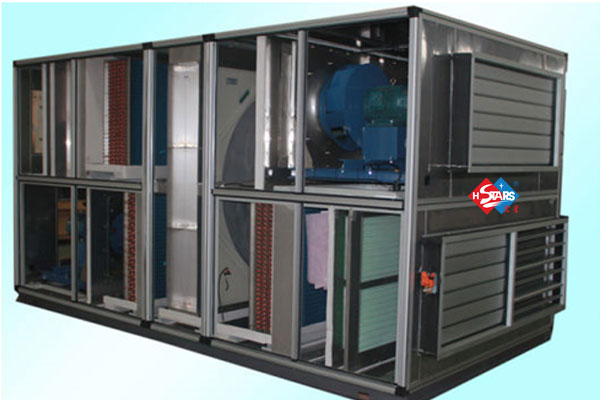

Industrial Air Dehumidifier can quickly, simply and effectively reduce the air humidity, and efficiently solve the dehumidification fields which cannot be achieved by other refrigeration methods, such as normal temperature and low humidity, low temperature and low humidity. Especially after the treatment of supporting combination, the air dew point can reach below - 70 ℃, and low-grade heat energy such as industrial residual heat, waste heat, solar energy, natural gas can be used as renewable energy, without environmental pollution and energy Low consumption. Widely used in food, medicine, electronics, electrical appliances, chemical industry, national defense, printing and other industries with humidity requirements. In high temperature and high humidity areas, adsorption wheel dehumidifier will play its unique advantages, which can bring huge economic benefits to enterprises on its commercial air handling unit.

he core part of the wheel dehumidifier is a honeycomb wheel, which is composed of special ceramic fiber carrier and active silica gel. The two sides of the wheel are divided into two areas by special sealing device: treatment area and regeneration area.

When the wet air to be dehumidified passes through the treatment area of the runner, the water vapor of the wet air is absorbed by the active silica gel of the runner, and the dry air is sent to the space to be treated by the treatment fan, while the continuously slowly rotating wheel carries the saturated water vapor into the regeneration area, and the high temperature air blown in the direction of the regeneration area makes the water adsorbed in the runner be desorbed and winded The unit is discharged out of the room, so that the runner can recover the moisture absorption capacity and complete the regeneration process on the field of air handler hvac.

With the continuous rotation of the runner, the above dehumidification and regeneration are carried out repeatedly, so as to ensure the continuous and stable dehumidification state of the dehumidifier. The new type of wheel dehumidifier adopts new dehumidification materials, which can break through the limit of low dew point when used with air conditioning return air device. Under the condition of low air humidity, the moisture absorption capacity is still strong, so the dehumidification effect of the new type of wheel dehumidifier is better for ahu dehumidifier.

Dsiccant dehumidifier ahu opating pinciples:

Supply Air Stream

Outside air is drawn into the unit using the supply fan. The warm, moist outside air first passes through filters and then the cooling coil where it is cooled. The air then goes through the desiccant wheel where the air is dehumidified and the temperature is raised. At last the air is delivered directly to the space or into an existing air handler.

Exhaust Air Stream

Exhaust air is used to provide energy recovery for the desiccant wheel and is drawn into the unit using the exhaust fan. The air filtered and then heated and humidified during the energy recovery process. The air is then heated while passing through the regeneration coil. The heated air removes the moisture that the desiccant wheel adsorbs from the process air stream.

Main features of H.Stars Industrial desiccant air dehumidifier hvac commercial air handling unit ahu:

1、 The runner runs slowly, the loss of internal gear, motor, runner and so on is little, and the service life is relatively longer. The quasi wheel cleaning of dehumidifier is very convenient.

2、 The hygroscopic material has stronger hydrophobicity and hygroscopic ability. Three

3、 Renewable energy does not require additional high-temperature heat sources or regeneration airflow. Four

4、 The cleaning process of dehumidifier is very convenient. The air cylinder, steam engine and vacuum cleaner can all be cleaned frequently to keep the equipment clean, which helps to improve the service life of the equipment. Five

5、 Dehumidifier operates in a wide range of temperature, and can be used normally in most temperatures.

6、 The hygroscopic material on the runner is covered on the runner by special methods, which is not easy to fall off.

In case where indoor and outdoor temperature difference is large ,fresh air treatment process would consumes high energy. With heat recovery wheel, the fresh air is pre-heated(pre-cooled) by recovering the residual heat in the exhaust air, thus much reduce the energy consumption.