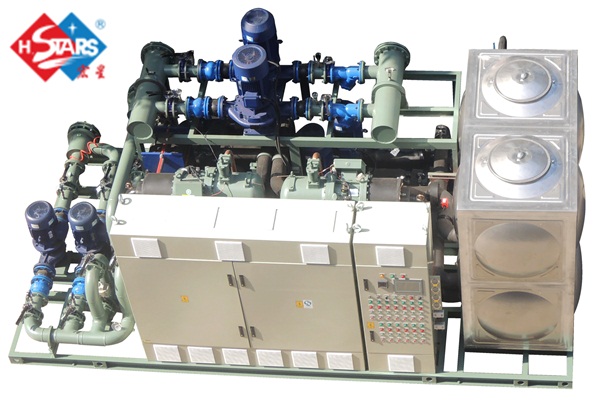

The industrial integrated all in one chiller unit can be designed with both air cooled chiller and water cooled chiller, which is an integrated equipment designed for the industrial application with built-in pump and built-in tank .

Industrial Chiller with Integrated Pump Packages Customized Chiller

Brief introduction:

They are integrated chiller system with hydraulic modules, including chilled water supplying pump, water tank and reservoir to simplify the installation and operation. The industrial integrated all in one chiller unit can be designed with both air cooled chiller and water cooled chiller, which is an integrated equipment designed for the industrial application with built-in pump and built-in tank . Integrated with the main components of chiller, chilled water preservation tank, chilled water circulating water pump, process water pump,waterway system , all kinds of valves, and engineering control cabinets. Combine the project parts during the production line to save engineering labor cost.

Main features of H.Stars Industrial Integrated All In One Chiller:

1) Fully Packaged chiller with Integrated Pump and Tank , designed for engineers at site with simple installation and time-saving.The chiller is assembled with built-in pump and tank ,as well as filled with refrigerant and lubricating oil during production, the customer only needs to connect the inlet & outlet pipes and the power supply to operate the unit. The control interface directly show the fault content, convenient to identify the fault and fix timely.

2) Lowest Operating Costs, Modular design, automatic load regulation, high efficiency under partial load.

3) Do not need the machine room and special management, reduce the investment in labor cost and civil engineering.

4) H.Stars customizes the chiller unit based on various industries and projects and tailor-make integrated all in one industrial chiller to different clients.

5) The chiller can be equipped with our own patented heat recovery unit and the heating capacity is above 30% of the cooling capacity, full heat recovery also available . The hot water temperature up to 70 ℃. No energy consumes during heat recovery, and the chiller efficiency increases by 5%.

6) Adopts microcomputer control to highly integrate through a centralized management system. Optional equipped with a remote management program to monitor sending feedback of system operation information to achieve remote control

service.

7) The chiller has been designed with 7 safety protection to ensure the unit running normally. Available in single and dual circuit designs to meet different customer requests. In case one of the compressors in dual compressor system fails, the other compressor can still be running ,to minimize the whole system shutdown risk from losses. Each equipment will be 100% tested by safety inspection system before shipping to ensure the chiller Performance in accordance with national standards.

Application:

1) Injection Industry

H.Stars all in one chiller can accurately control the temperature of mold which can improve the quality and production rate.

2) Electronic Component Industry

H.Stars all in one chiller can stabilize the molecular structure of electronic component inside. This can improve the FTQ and product time.

3) Machinery Industry

H.Stars all in one chiller can cool down the oil for the machine and stabilize the oil temperature and pressure. It'll extend the useful life of oil. And it can also improve mechanical lubrication efficiency.

4) Electroplating Industry

The temperature of electroplate can be controlled by our chiller. It can improve the density and smooth of electroplate and production efficiency.

5) Food & Drink Processing Industry

The temperature of processed food and drink will be too high to be packaged. H.Stars chiller can cool it down through food grade stainless steel heat exchanger.

6) Air conditioner system

Widely used in building air conditioning system, small and medium-sized office, workshop, restaurants, villas and other air conditioning environment.