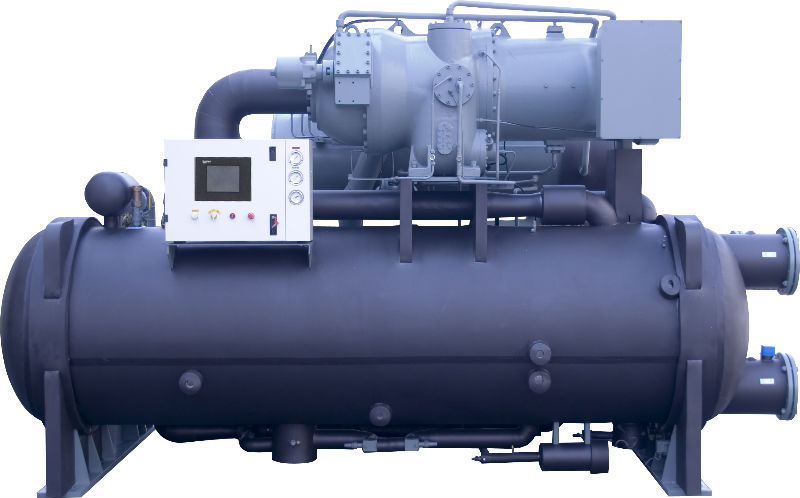

2 Stages water cooled Centrifugal Chiller with cooling capacity range from 500RT~1500RT. Centrifugal chiller is highly reliable, high-performing, and so future-proof that once it’s installed, you may never have to think about it again. Moreover, it costs low maintain cost.

Flooded Type Centrifugal Chiller Water Cooled Chiller

The main components of centrifugal chillers are semi-closed two-pole centrifugal compressors, spray-type (falling-film)evaporators, refrigerant liquid re-circulation systems, flash-type economizers and orifice plate throttling devices.

Centrifugal chiller parameters:

Frozen water temperature range: 5-20 ° C

Cooling water temperature range: 15-40 ° C

Application: Mainly used in central air conditioning systems and industrial process cooling.

Centrifugal chiller features:

1. Centrifugal chiller has built-in oil cooler, which is cooled by refrigerant and requires no maintenance.

2. Use an independent oil return system (injection pump return oil) to ensure timely oil return under any load conditions.

3. The oil pump is built in the compressor oil tank of the unit, and the oil pump has no leakage.

4. The centrifugal chiller adopts the fixed orifice plate throttling device and has no moving parts. Under the variable load conditions, the refrigerant flow can be adjusted in time without hysteresis to ensure the stable operation of the unit.

5, low-voltage unit, using soft start cabinet step-down start, the start-up process will not impact the use of the grid.

6, high-voltage units, the use of high-voltage start-up cabinets, which are equipped with integrated protectors, including blocking, phase loss, over current, over voltage and other functions.

7. The unit microcomputer control system uses full Chinese painting to clearly display the various operating data, and the operation is extremely convenient.

Company Information:

Packaging & Shipping:

1)wooden case with assemble package

2) plateform with unassemble package

3) assemble package with EPE foma and bubble film

1,Wooden pallet base

2,With transparent package film well protect machine

3,For side go with buffer panel well protect machine during shipping period

Certifications: